Imagine a world where our homes are not built from lifeless concrete, but from living, breathing organisms. This may sound like a scene from a futuristic novel, but the reality is closer than you might think. Researchers are on the brink of revolutionizing the construction industry with a material that grows, adapts, and even repairs itself—a material made from fungi and bacteria. This groundbreaking study, published in the journal Cell Reports Physical Science, has taken us one step closer to a future where sustainable, living architecture is not just a dream, but a tangible reality.

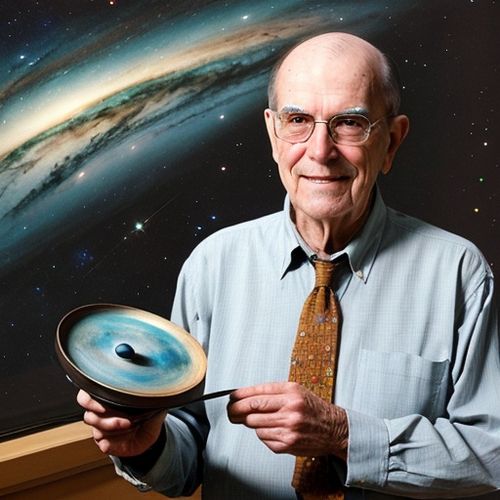

The quest for a sustainable alternative to cement is both urgent and necessary. Cement production is a colossal contributor to global carbon dioxide emissions, accounting for a staggering 8% of the world’s total emissions. If cement were a country, it would be the third-largest emitter of CO₂, trailing only China and the United States. In a world grappling with climate change, the need for innovative solutions is more pressing than ever. This is where the vision of Chelsea Heveran, the senior author of the study, comes into play. Heveran, an assistant professor of mechanical and industrial engineering at Montana State University Bozeman, has dared to ask, “What if we could do it a different way using biology?” This simple yet profound question has set the stage for a potential paradigm shift in construction.

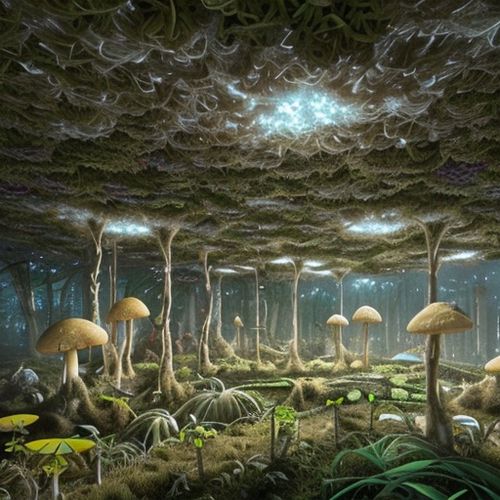

At the heart of this innovation lies mycelium, the intricate, root-like structure that forms the foundation of fungal networks. Mycelium is not just a fascinating natural phenomenon; it is a robust and versatile material with remarkable potential. The research team in Montana has harnessed this potential by cultivating dense, spongy tangles of mycelium to serve as the framework for a living, self-repairing building material. Imagine a material that grows like a plant, adapts to its environment, and can even heal itself when damaged. This is the promise of mycelium-based construction.

However, mycelium alone is not enough. To transform this flexible, organic material into something that can support the weight of a building, the researchers introduced a key player: bacteria. Specifically, they used Sporosarcina pasteurii, a type of bacteria capable of producing calcium carbonate. This chemical compound, found in coral, eggshells, and limestone, is renowned for its strength and durability. Through a process known as biomineralization, the calcium carbonate produced by the bacteria hardens the mycelium into a stiff, bone-like structure. The result is a material that combines the organic, self-sustaining properties of fungi with the structural integrity needed for construction.

The brilliance of this approach lies in its ability to keep the bacteria alive and active for extended periods. Unlike other biomineralized building materials that only remain “alive” for a few days, Heveran’s team managed to keep the microbes active for at least four weeks. With further research, this period could potentially extend to months or even years. This longevity is crucial because it opens up a world of possibilities. Imagine walls that can detect poor air quality and light up as a warning, or materials that can seal cracks autonomously. These are not just futuristic ideas; they are within reach thanks to the living nature of this new building material.

The potential applications of mycelium-based construction are as vast as they are exciting. While it may take five to ten years before we see these materials used in large-scale construction, the possibilities are already being explored. Single-story buildings, fences, and other smaller structures could be the first to benefit from this innovation. The flexibility of mycelium allows it to be shaped into various forms, including beams, bricks, and walls. Moreover, the material’s ability to incorporate vascular-like channels for nutrient delivery could pave the way for truly living structures. However, this also presents a challenge: adding such structures could potentially weaken the material. Balancing strength and functionality will be a key focus of future research.

Despite the promise of mycelium-based construction, there are still hurdles to overcome. One significant concern is the potential respiratory hazards posed by fungi. While killing the mycelium reduces its allergen-producing ability, more research is needed to ensure its safety for human habitation. Additionally, regulatory standards for living building materials are virtually non-existent. Creating a framework to evaluate the strength, durability, and safety of these materials will be essential before they can be widely adopted.

The journey towards sustainable construction is not without its challenges, but the potential benefits are immense. For society, the cost savings of using living building materials could be significant, especially in areas where infrastructure is desperately needed. Imagine building homes in remote or underdeveloped regions without the need to transport heavy, expensive cement. Or consider the possibilities of constructing habitats in space, where traditional materials are impractical. The potential applications are limited only by our imagination.

As we stand on the brink of this new frontier in construction, it is important to recognize the pioneering work of researchers like Chelsea Heveran and her team. Their vision of a world where buildings are not just structures, but living, breathing entities, is both inspiring and revolutionary. While it may be some time before we see fungus bricks sold at our local home improvement stores, the future of sustainable construction is already taking shape. The possibilities are indeed exciting, and the journey ahead promises to be as transformative as it is groundbreaking.

By Sophia Lewis/May 6, 2025

By Olivia Reed/May 6, 2025

By William Miller/May 6, 2025

By Eric Ward/May 6, 2025

By John Smith/May 6, 2025

By Rebecca Stewart/May 6, 2025

By Benjamin Evans/May 6, 2025

By Eric Ward/May 6, 2025

By Eric Ward/May 6, 2025

By Daniel Scott/May 6, 2025

By Benjamin Evans/May 6, 2025

By Elizabeth Taylor/May 6, 2025

By James Moore/May 6, 2025

By Victoria Gonzalez/May 6, 2025

By Sophia Lewis/May 6, 2025

By Laura Wilson/May 6, 2025

By Olivia Reed/May 6, 2025

By David Anderson/May 6, 2025

By Olivia Reed/May 6, 2025

By Sophia Lewis/May 6, 2025